Grasping DTF Printing: A Comprehensive Guide to Direct-to-Film Techniques

From Concept to Creation: Letting Loose Creative Thinking With DTF Printing on Various Fabrics

In today's vibrant realm of textile layout, the use of Direct to Film (DTF) printing modern technology has changed the process of transferring detailed layouts onto various textiles. The fusion of technology and virtuosity with DTF printing opens up doors to a realm where imagination knows no bounds.

Checking Out the Perks of DTF Printing

Why is DTF printing increasingly liked over other techniques for its adaptability and resilience in the textiles market? Direct-to-film (DTF) printing has been gaining traction in the fabrics sector due to its various advantages that satisfy the developing requirements of the market. One essential advantage of DTF printing is its versatility in regards to the materials it can be applied to. Unlike some typical techniques that are restricted to certain fabric kinds, DTF printing can be utilized on a large array of materials, consisting of cotton, polyester, blends, and even natural leather. This adaptability enables better creativity and innovation in textile style.

Furthermore, DTF printing provides remarkable toughness, making it ideal for producing long-lasting styles on textiles - DTF Printing. The prints created via DTF are understood for their vibrant shades and resistance to fading, cracking, or peeling - making certain that the final product preserves its high quality also after multiple washes or expanded usage. This resilience makes DTF printing a cost-efficient option for producers seeking to create premium, long-term layouts on fabrics

Creating With DTF: Advice

Creating properly with DTF printing involves grasping the complexities of digital style software and recognizing how to maximize styles for the very best outcomes on various textiles. When creating layouts for DTF printing, it is vital to consider the fabric type, color, and structure to ensure that the last product fulfills assumptions. Here are some techniques and ideas to enhance your DTF style procedure:

Resolution is Trick: Begin with high-resolution photos to preserve clarity and sharpness in your styles. Low-resolution images can result in a pixelated end product.

Color Matching: Pay focus to shade accuracy when making for DTF printing. Usage color monitoring tools to make sure that the colors in your style equate precisely onto the textile.

Vector Graphics: Use vector graphics anywhere possible to maintain the top quality of your designs when scaling them to different dimensions. (DTF Printing)

Test Prints: Constantly perform test prints on sample materials to examine the shades, resolution, and total layout high quality before full-blown manufacturing.

Choosing the Right Fabrics for DTF

When thinking about the optimal fabrics for DTF printing, the option of material plays a crucial function in achieving the preferred quality and resilience of the last printed layouts. Fabrics with a high polyester web content are generally chosen for DTF printing due to their capability to hold the ink well and generate vivid prints. By carefully choosing the ideal material for DTF printing, developers can improve the longevity and aesthetic effect of their styles.

Step-by-Step DTF Printing Process

After curing, the printed layout is then transferred onto the material using a warmth press. The transfer process requires careful positioning to guarantee that the style is applied accurately. Once the transfer is full, the fabric is allowed to cool before the transfer movie is removed, leaving the resilient and dynamic style on the textile. The textile might undertake post-processing therapies to enhance the design's long life and vibrancy, resulting in a top quality completed item prepared for usage or screen.

Showcasing DTF Masterpieces

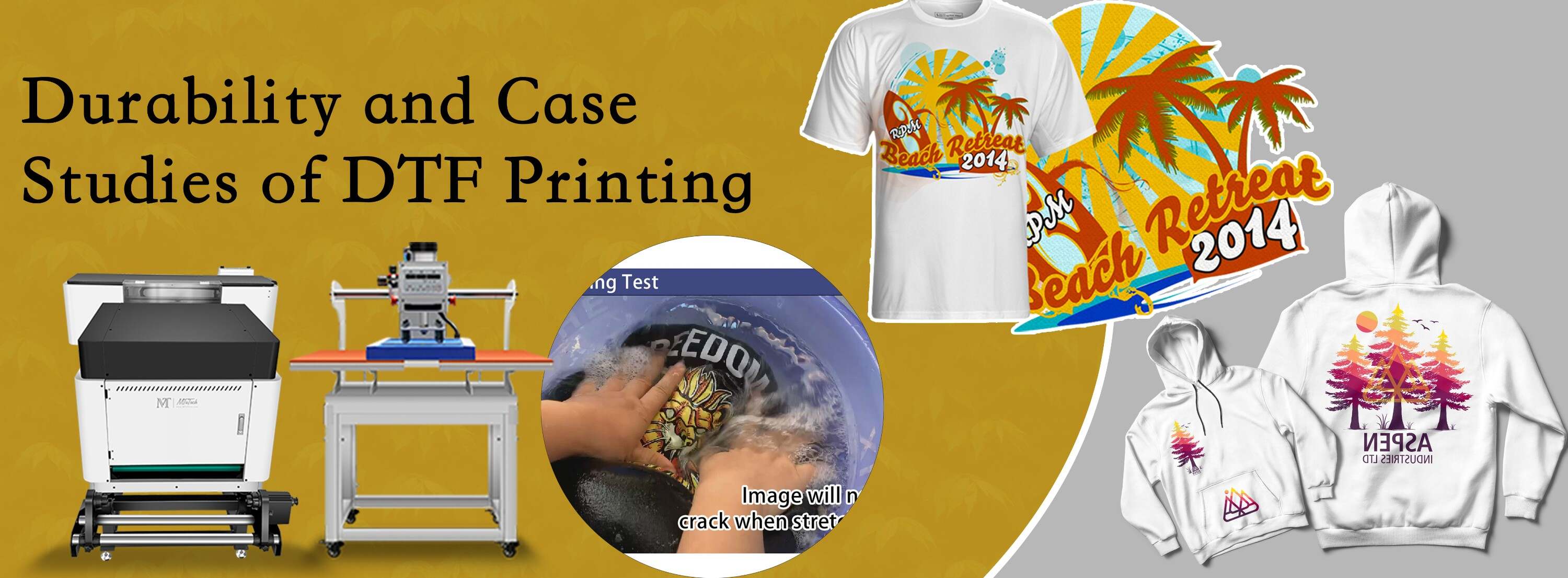

Have you ever before wondered at the intricate information and vibrant colors of DTF masterpieces showcased on numerous fabrics? DTF printing has actually transformed the way styles are transferred onto textiles, permitting unmatched precision and splendor in colors. When these DTF work of arts are placed on screen, they mesmerize target markets with their striking visuals and careful workmanship.

Among one of the most exciting elements of showcasing DTF masterpieces is the adaptability it supplies. Whether it's a appealing and bold design on a tee, a thorough pattern on a pillowcase, or a custom-made print on a canvas bag, DTF printing enables countless possibilities. This flexibility allows musicians and designers to release their imagination and bring their visions to life on a wide variety of textiles.

Furthermore, the durability of DTF prints makes certain that these work of arts can hold up against the examination of time without shedding their vibrancy. Whether presented in galleries, worn wikipedia reference as fashionable garments, or utilized as attractive accents in homes, DTF masterpieces continue to impress audiences with their outstanding top quality and aesthetic charm.

Final Thought

Finally, DTF printing supplies a ingenious and versatile method for unleashing imagination on numerous materials. By discovering the benefits of DTF printing, making with specific tips and tricks, picking appropriate textiles, and following a step-by-step printing process, musicians can display their work of arts with convenience. This procedure permits the smooth shift from principle to development, providing countless possibilities for innovative expression.

In today's dynamic realm of fabric layout, the utilization of Straight to Film (DTF) printing innovation has transformed the procedure of moving complex designs onto different fabrics.Creating successfully with DTF printing involves grasping the ins and outs of electronic style software application and understanding exactly how to optimize styles for the best outcomes on different textiles.When taking into consideration the ideal materials for DTF printing, the option of product plays a critical function in attaining the Clicking Here wanted high quality and resilience of the last printed designs. The following step is publishing website here the layout onto an unique DTF transfer film using a DTF printer with the appropriate ink. By discovering the benefits of DTF printing, making with specific pointers and tricks, picking suitable materials, and adhering to a detailed printing procedure, musicians can showcase their work of arts with simplicity.